When tasked with writing a feature article about one of the most followed builds on the interwebz, which has been wonderfully documented in countless blogs about the build progress and even a feature length documentary (watch below) about the journey, it would be easy to write a novel on the technical specs, jaw-dropping details, and seemingly endless custom made parts. Some builds however, to truly understand the vehicle, one needs to look beyond the steel, the fibreglass, the shiny parts and the horsepower figures, and get to the essence of what it truly is about. Understanding Nigel Petrie’s one-off space-framed drift-spec Toyota Hilux is best done by understanding the man who built it, as it is such an extension of him and the story of how it came to be the truck that you see in these photos.

Photos: Brian Goude & Roo Wills | Words: Nick Maarhuis

Photos: Brian Goude & Roo Wills | Words: Nick Maarhuis

Much like many owners of Slam’d feature vehicles, Nigel is first and foremost, a creator and artist. Like many of us, he sees not what is, but would could be, and draws from personal influences to create something new – all with common tools, his bare hands, and never-ending perseverance to reach his goals. As may have been expected, he has a love for both minitrucks and drift cars, having dabbled in air suspension with a slammed Hilux, and competing in drifting at the top level around his home country of Australia with his full drift-spec Nissan 180SX. Automotive mash-ups aren’t necessarily anything new, and although the Nissan SR20DET powered Hilux is truly unique and incredibly built, possibly the even more interesting story is how it came to be.

Nigel’s brand is Engineered To Slide, which has grown massively over the past three years alongside the build and development of not only the Hilux, but also the maintaining, development and competing with his drift car. As if that wasn’t enough, Nigel also is underway with custom/modified bike builds, an extensive garage fit-out at a new location, custom scratch-built bagged trailer build, a motorbike trailer build, custom bmx, building his own tools (such as a tube bender to make the Hilux frame) and more. In between, and for a bit of fun he also has various other things going on like developing and building SR20 and drift parts for other people, random fun stuff like THIS, screen printing his own merchandise, doing blog posts and website development, and also building a very crazy, very custom Nissan Silvia in the works.

This all sounds very appropriate for a team at a custom workshop, you may be thinking, but the incredible thing is that not only is Nigel the sole person doing all these amazing things, he is somehow doing it outside of his 40 hour work week at his day job! Possibly to achieve all of this he’s a vampire and doesn’t sleep, but that can neither be confirmed or denied. What can be confirmed is that he has great support from his lovely wife Celia, who he recently married. Some of the few things on the Hilux he’s not fully done himself include having some help from Andre at HP Academy with creating a fully one-off mil-spec wiring loom, and setting up and engine tuning of the Link ECU.

Back to the aforementioned things you can’t see in photos or the spec sheet to understand this build, is one of the reasons Nigel is such an inspiration for those who follow his activities online. When he started the build, not only was it in a single car garage at his home (he would roll the frame out on a trolley to work on it outside), but that the majority of his welding and fabrication skills have been developed throughout the build. An example of this is that the base of the space-frame (tube frame) was initially mig welded, and then after learning to tig weld he tig’d the rest of it, but then the whole base of the frame was cut out and re-fabricated so that it could be tig’d and up to the same quality standard as the rest. Similarly with many other parts and features on the Hilux, things were developed over time and Nigel continually pushed himself and the build as his abilities and skill sets grew.

This is not to say that the initial designs or parts were less than amazing, but that things can always be better and if you push yourself to strive for excellence, it can be achieved. Not knowing how to do something is not an excuse, as it can be learned at any stage in life. Not having the budget for certain parts is not an excuse, because some things can be custom made for less money, if you’re willing to put the time into it. A part you want doesn’t even exist? Imagine it, draw it, prototype it, test it, develop it, and you will have it. Even outside of the workshop and fabrication, in parallel with the development of the Hilux, Nigel learned photography, so that as the build progressed so did the photos of the build and quality was achieved on all fronts.

In summary, this build represents so much more than the amazing design, engineering and style that went into it; it is a piece of functional art that is just as good at being ogled for hours stationary, as it is at going sideways at 100+ mph with smoke bellowing off the tires. This Hilux represents what can be achieved when ordinary people with ordinary means put extraordinary passion and effort into a project, to bring their dreams to life. As Napoleon Hill famously said, “whatever the mind can conceive and believe, it can achieve” and Nigel Petrie is certainly testament to that. For more info on the build, watch the documentary below, check out the Spec box for more details, and click through the Slam’d Mag gallery to see more exclusive photos.

Full Length Documentary:

Slam’d Specs

Suspension/Chassis:

Suspension/Chassis:

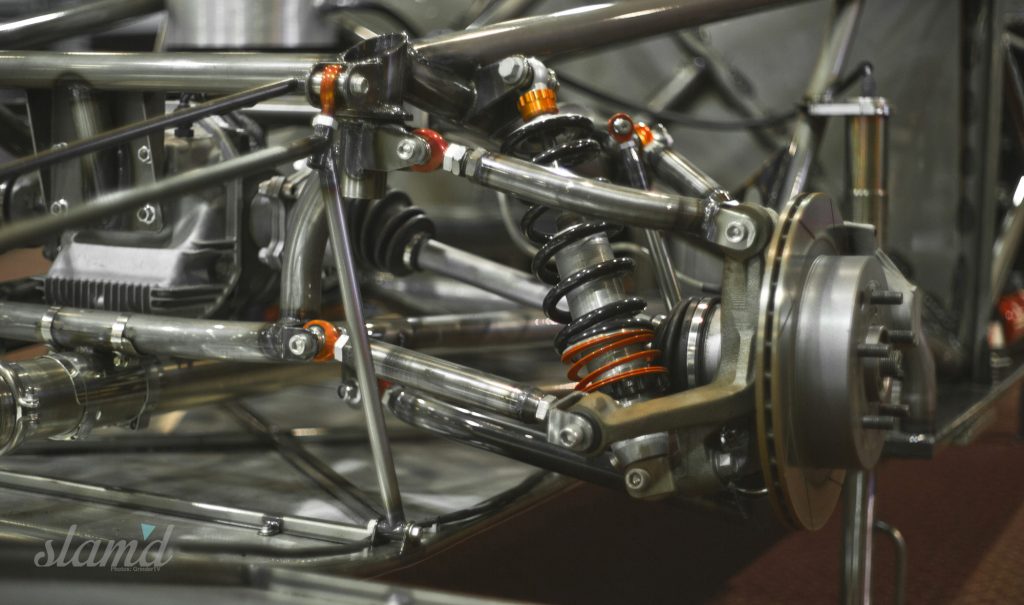

Scratch-built space frame, mostly 16mm, 25mm, 38mm and 45mm cold drawn seamless tube

2700mm wheelbase (150mm longer than a “shorty” minitruck, and shorter than a standard Hilux)

Front: Nissan Silvia S13 McPherson strut design

Rear: Nissan Silvia S15 knuckles and layout, arms and pick up points re-built from chromoly tube, rose joints and sheetmetal tabs all cut by hand, race-spec chromoly blade-adjustable swaybars, custom-built shocks from MCA suspension, and custom-built steering column

Out back the chassis holds an undertray that finishes off a complete flat alloy floor and diffuser setup, the front and rear clip are all removable to allow ease of repair and access to everything

The fuel tank is a spun upright tank that holds 30 litres of 98 pump fuel

Engine/Performance:

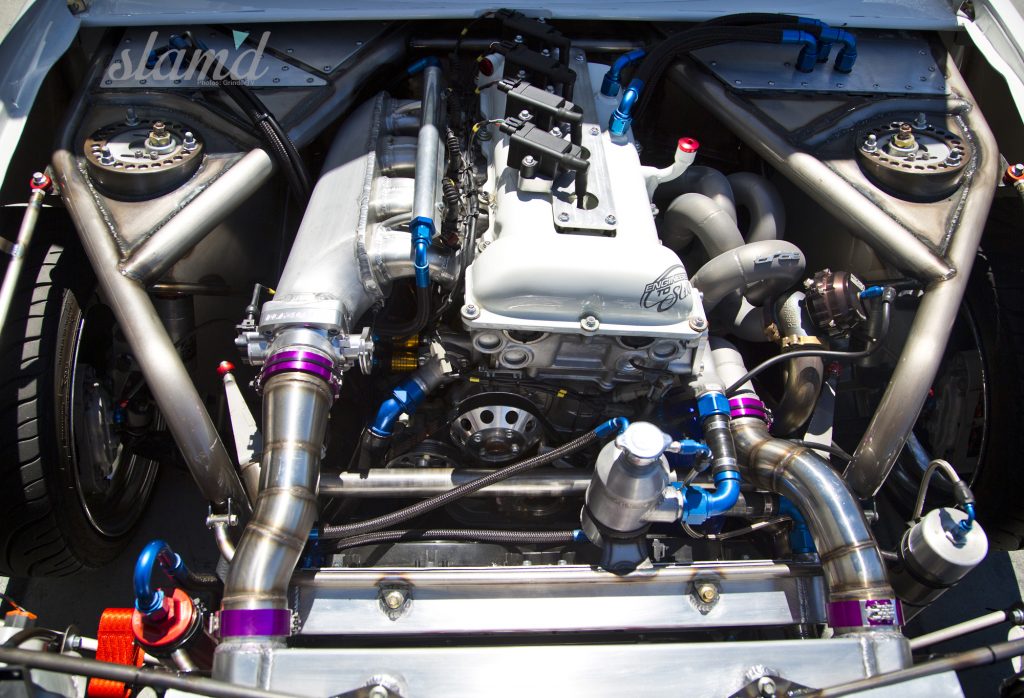

Race-prepped rebuilt Nissan SR20DET (S13 version) with larger cams, metal headgasket and ARP hardware

GReddy Trust TD06L2 20G 8cm turbo and custom steampipe manifold, Precision 46mm wastegate, Wiggins clamps, custom stainless intercooler piping, custom PWR intercooler, CNC inlet runners and cast plenum using 1000cc injectors and Powerflow fuel pressure regulator

3-inch straight through stainless exhaust

Powermaster high-output alternator

Link ECU and coils

Custom HPA mil-spec engine loom with quick disconnect firewall plug, shaved rocker cover, custom water flow tank, inbuilt oil catch can in the chassis, custom power steering reservoir in the chassis, custom everything!

325 rwkw (436rwhp) / weight 900kg (1984 lb)

CNC adapter to Quaife QBE69G sequential dog box, internal hydraulic clutch release, Exedy twin plate clutch, chromoly tail shaft with Strange unijoints, S13 R200 differential with 2-way Carbon Pack clutchpack Wilwood overhung pedal box

Body/Mods:

Body/Mods:

2001 Toyota Hilux (the Australia/NZ/Japan version of a Tacoma) oem steel outer cab (purchased as a bare shell)

Shaved rain gutters, factory steel doors with shaved handles, FRP (fiberglass reinforced plastic) bonnet, FRP rear quarters (lengthened and flared), FRP tailgate, FRP front quarters (flared), factory grille

Raybrig headlights, Factory bumper and valance

Painted in Factory Toyota Superwhite by Tim Harrison at Breakwater Panels Victoria, Australia

Interior/Cabin:

Bride Vios III race seats

Racepak dash and smartwire control unit with roof mounted switch panel

Nardi steering wheel

Custom alloy interior panels

Simpson harnesses

Special Thanks:

Bob and Laurie at IPTA, Pavel, wife Celia, my family, Tim Harrison, Andre and Ben from High Performance Academy, and everyone who follows and supports custom creations and the people who bring them to fruition.